Backtracking Forward: Behind The Scenes

posted in: Features

It was a cold Tuesday night back in 2005 and the cargo van was filled with musicians, equipment and merch headed to the next show. A long day of driving had taken its toll on the van’s passengers who were itching to reach their destination, stretch their muscles and play a gig. Just outside of the city limits, the bass player turned to the haggard crew and announced a surprise stop. Before anyone could muster a peep of curiosity, he turned to me and said, You’ll never forget this night. With that statement still rolling off his tongue, the van pulled into the parking lot of United Record Pressing in Nashville, TN and for the first time in my life, I truly felt like a kid in a candy store.

It was a cold Tuesday night back in 2005 and the cargo van was filled with musicians, equipment and merch headed to the next show. A long day of driving had taken its toll on the van’s passengers who were itching to reach their destination, stretch their muscles and play a gig. Just outside of the city limits, the bass player turned to the haggard crew and announced a surprise stop. Before anyone could muster a peep of curiosity, he turned to me and said, You’ll never forget this night. With that statement still rolling off his tongue, the van pulled into the parking lot of United Record Pressing in Nashville, TN and for the first time in my life, I truly felt like a kid in a candy store.

In between fits of awe and giddiness on the tour of United Record Pressing, I was able to take some photos that captured the mystique of making vinyl records. By no means am I an expert on the subject and in fact, I highly recommend checking out the links at the end of this post for more detailed and specific explanations on how vinyl records are made. But the text and pictures outlined below is the result of a veteran record collector being reduced to the level of a giddy school girl when taken behind the scenes of the most fascinating manufacturing process.

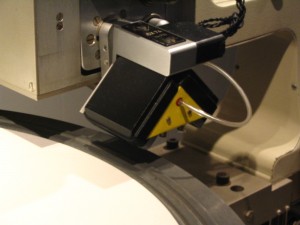

Creating The Master Disc From A Lacquer Cutting Machine

The Final Product Is Used To Create Stamping Plates

Blank Lacquers Sit On Top Of The Machine That Sets The Size And Speed Of The Record When It Is Cut

The job of the cutting engineer, which is one the most important functions of the plant and the discs it presses, is confined to a clean and comfortable work space to ensure quality control. Upon leaving the engineer’s office, we traversed to the belly of the pressing plant where things get a little dirty. Once the master disc is created, “Mother” and “Father” discs are made to use for the manufacturing of the actual records and the master disc is stored away in a climate controlled environment.

Coating The Master Discs With Nickel And Other Acids

The Master Is Then Coated With A Layer Of Silver

The silver is sprayed onto the master to enable it to conduct electricity and the nickel bath it receives creates the stampers used for pressing.

Paper Labels Waiting To Be Placed On Their Respective Vinyls

By this point, I had witnessed things I never experienced before and touched things that gave me goosebumps of excitement. We then turned a corner that opened up into a massive production room and I fell to my knees in a fit of ecstasy and amazement as I saw the final process of how vinyl records are made.

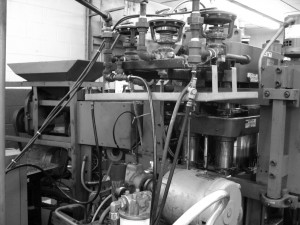

The Final Step In Manufacturing

Globs Of Melted PVC Go In And The Record On Your Turntable At Home Comes Out

If You Own This Record, I Might Have Touched It When It Came Out Of The Press! Or Breathed On It!

Although this plant does not recycle old vinyl albums to use for pressing new records, they will reuse defective vinyl for more pressings.

- Defective Vinyl From The Plant Is Reused For More Pressings

- The Excess Vinyl Trimmed Off From Every Platter That Is Made Is Collected For Reusing.

The last stop on the tour brought us into the hallway of master discs. Once a master is created, repressing the same disc is quite speedy and URP houses many of the masters for future re-pressings.

- Despite Popularity, Genre Or Wealth, All Masters Are Created And Housed Equally

Manufacturing vinyl records is not a simple procedure. The average record collector has no idea what goes into making the platter that spins on their turntable yet this ambiguity adds to the appeal of vinyl. Once the process is known, a whole new level of respect and admiration is bestowed upon the oldest recorded medium used for providing music to the masses.

Check out the video below from the History Channel’s segment on pressing vinyl records at Rainbo Pressing Plant in California.

Keep Digging!

-Gregorious-